What Are the Most Important Fleet Management Metrics to Track?

If your business relies on a working fleet in its daily operations, it’s absolutely vital to get the most possible value from those vehicles. Costs of fleet ownership continue to go up, especially fuel costs and replacement electronics, so a smart fleet manager should be constantly tracking data and looking for the best ways to optimize operations.

A great fleet maintenance management software solution provides the tools to collect, track, and analyze vast amounts of data – but it takes the human touch to know which pieces of information are most important.

At VLC, we have extensive experience helping fleet managers make the most of their vehicles – and these are the metrics we tell our clients to always focus on.

Ten Critical Metrics to Track For Optimizing Your Fleet Maintenance Management

1 – Daily Vehicle Inspection Reports (DVIR)

Your DVIRs are one of the single most important data sets you can collect. Yes, they can alert you to immediate problems with the vehicles, but their real value is long-term. Properly stored and analyzed, they give you deep insights into the health and performance of every vehicle. In many cases, you even get early warnings of maintenance issues before they become a big problem.

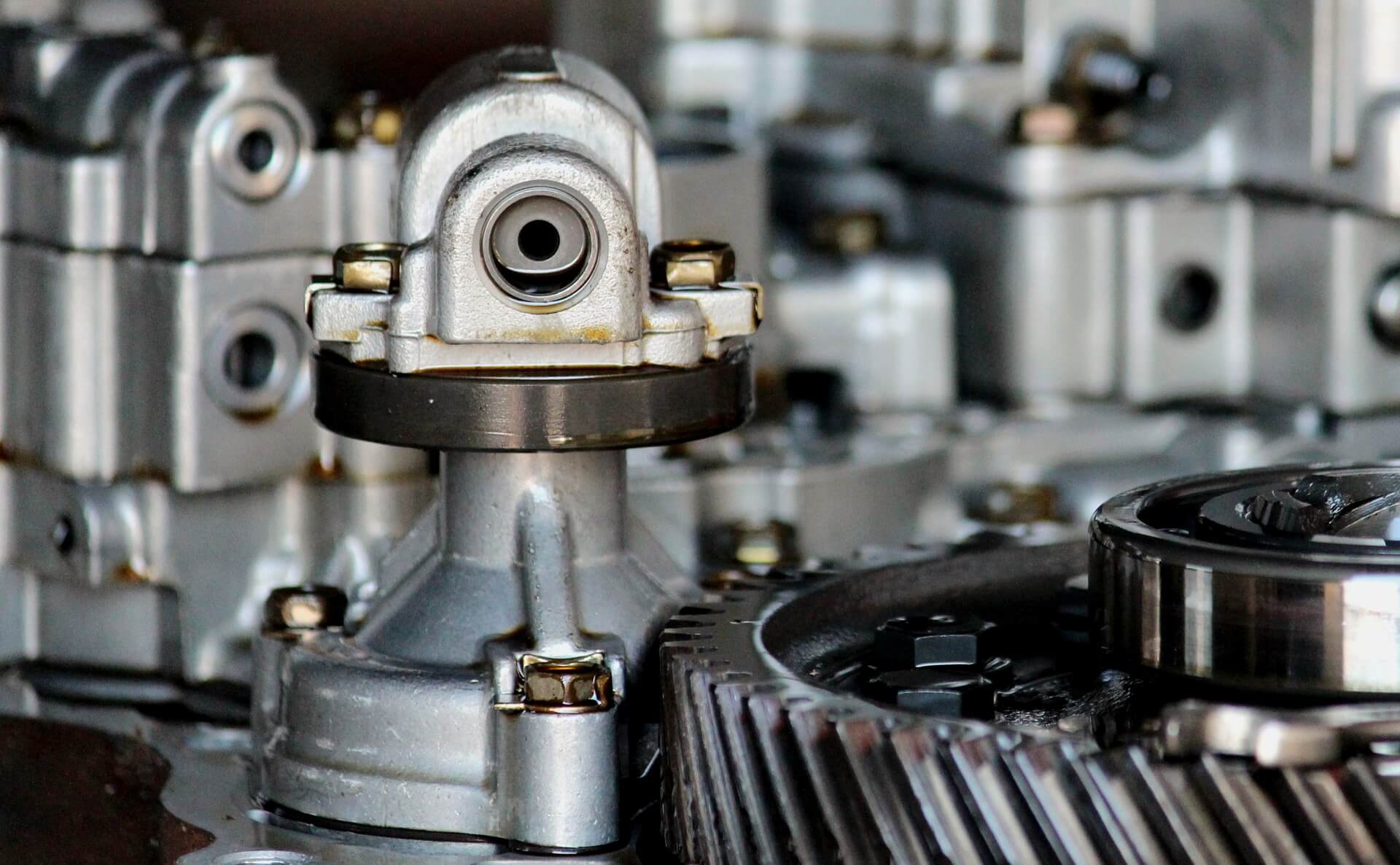

2 – Component lifespans

Every component in your vehicle has an expected lifespan, typically measured in either years or miles. This information is almost impossible to track by hand, but a fleet maintenance management system can track your vehicles at the component level. You’ll have early warnings that a component is near its EOL, allowing you to proactively replace it before a breakdown happens.

3 – Miles and gas mileage

Fuel costs are difficult to manage even in the best of times, and right now, anything you can do to improve your vehicles’ MPG is going to significantly reduce ongoing costs. By tracking the odometer and gas mileage over time, you’ll know early on if some sort of problem is affecting performance. It might be a mechanical issue or a bad driving habit, but either way – you’ll be able to address the problem sooner, rather than later.

4 – Asset utilization

Accurately tracking the utilization of your vehicles is critical for avoiding both over-and under-utilization. An under-utilized vehicle either needs to be used more or else potentially be removed from service to avoid the maintenance costs. Over-utilized vehicles are going to be less reliable and prone to breakdown, and – at least – need more maintenance attention to keep them running at peak performance.

5 – Total maintenance costs

How much are you spending per vehicle to keep it on the road? And is this expense actually justified by its returns? Too often, fleet managers can get into the habit of simply paying for repairs and maintenance, without doing a TCO/ROI breakdown on those costs. If a vehicle has become a money pit, you should know as soon as possible so that you can start exploring alternatives.

6 – Stock inventory

If your business truly relies on having vehicles on the road at all times, it’s vital to keep enough spare parts in your inventory to do replacements as quickly as possible. However, this can be tricky if you’re trying to track all your spares by hand. Good fleet management systems incorporate inventory management tracking as well, so you’ll always know when it’s time to order more spares – before they’re required.

7 – Driver performance and safety

When your fleet management software is linked to vehicle telematics systems, you don’t only get information about the vehicle – you also have a powerful tool to monitor driver performance as well. From staying within the speed limit, to whether they stop at train crossings, you’ll know whether they’re driving in ways that are safe and efficient. If not, it’s time for some coaching.

8 – Driver assignments and profitability

Some drivers are better at some tasks than others; that’s just human nature. With good data tracking and oversight of your drivers, it’s easier to spot both their strong points and their weak points. This leads to much smarter driver assignments, allowing you to make the most of your human resources as well as your vehicle resources.

9 – Technician productivity

Which of your technicians are working the hardest, and who does the best work which stands up over time? This can be derived from your maintenance records, cross-referenced with the responsible technician. This opens new opportunities to optimize your technical staff while spotting workers in need of more coaching or training.

10 – TCO / ROI

All of this adds up to the ability to track the most important metrics of all: TCO and ROI. You’ll know in detail how much you’re spending on your trucks, their efficiency, and their value to the company. From purchasing decisions to governmental reporting, this information is invaluable.

We Have the Fleet Maintenance Management Solutions You Need

VLC helps you make the most of your working fleet! Click here to learn more about our services.