Fleet Management

What Are the Most Important Fleet Management Metrics to Track?

If your business relies on a working fleet in its daily operations, it’s absolutely vital to get the most possible value from those vehicles. Costs of fleet ownership continue to go up, especially fuel costs and replacement electronics, so a smart fleet manager should be constantly tracking data and looking for the best ways to optimize operations.

A great fleet maintenance management software solution provides the tools to collect, track, and analyze vast amounts of data – but it takes the human touch to know which pieces of information are most important.

At VLC, we have extensive experience helping fleet managers make the most of their vehicles – and these are the metrics we tell our clients to always focus on.

Ten Critical Metrics to Track For Optimizing Your Fleet Maintenance Management

1 – Daily Vehicle Inspection Reports (DVIR)

Your DVIRs are one of the single most important data sets you can collect. Yes, they can alert you to immediate problems with the vehicles, but their real value is long-term. Properly stored and analyzed, they give you deep insights into the health and performance of every vehicle. In many cases, you even get early warnings of maintenance issues before they become a big problem.

2 – Component lifespans

Every component in your vehicle has an expected lifespan, typically measured in either years or miles. This information is almost impossible to track by hand, but a fleet maintenance management system can track your vehicles at the component level. You’ll have early warnings that a component is near its EOL, allowing you to proactively replace it before a breakdown happens.

3 – Miles and gas mileage

Fuel costs are difficult to manage even in the best of times, and right now, anything you can do to improve your vehicles’ MPG is going to significantly reduce ongoing costs. By tracking the odometer and gas mileage over time, you’ll know early on if some sort of problem is affecting performance. It might be a mechanical issue or a bad driving habit, but either way – you’ll be able to address the problem sooner, rather than later.

4 – Asset utilization

Accurately tracking the utilization of your vehicles is critical for avoiding both over-and under-utilization. An under-utilized vehicle either needs to be used more or else potentially be removed from service to avoid the maintenance costs. Over-utilized vehicles are going to be less reliable and prone to breakdown, and – at least – need more maintenance attention to keep them running at peak performance.

5 – Total maintenance costs

How much are you spending per vehicle to keep it on the road? And is this expense actually justified by its returns? Too often, fleet managers can get into the habit of simply paying for repairs and maintenance, without doing a TCO/ROI breakdown on those costs. If a vehicle has become a money pit, you should know as soon as possible so that you can start exploring alternatives.

6 – Stock inventory

If your business truly relies on having vehicles on the road at all times, it’s vital to keep enough spare parts in your inventory to do replacements as quickly as possible. However, this can be tricky if you’re trying to track all your spares by hand. Good fleet management systems incorporate inventory management tracking as well, so you’ll always know when it’s time to order more spares – before they’re required.

7 – Driver performance and safety

When your fleet management software is linked to vehicle telematics systems, you don’t only get information about the vehicle – you also have a powerful tool to monitor driver performance as well. From staying within the speed limit, to whether they stop at train crossings, you’ll know whether they’re driving in ways that are safe and efficient. If not, it’s time for some coaching.

8 – Driver assignments and profitability

Some drivers are better at some tasks than others; that’s just human nature. With good data tracking and oversight of your drivers, it’s easier to spot both their strong points and their weak points. This leads to much smarter driver assignments, allowing you to make the most of your human resources as well as your vehicle resources.

9 – Technician productivity

Which of your technicians are working the hardest, and who does the best work which stands up over time? This can be derived from your maintenance records, cross-referenced with the responsible technician. This opens new opportunities to optimize your technical staff while spotting workers in need of more coaching or training.

10 – TCO / ROI

All of this adds up to the ability to track the most important metrics of all: TCO and ROI. You’ll know in detail how much you’re spending on your trucks, their efficiency, and their value to the company. From purchasing decisions to governmental reporting, this information is invaluable.

We Have the Fleet Maintenance Management Solutions You Need

VLC helps you make the most of your working fleet! Click here to learn more about our services.

Fleet Management

How Data-Based Fleet Maintenance Management Improves Your Operations

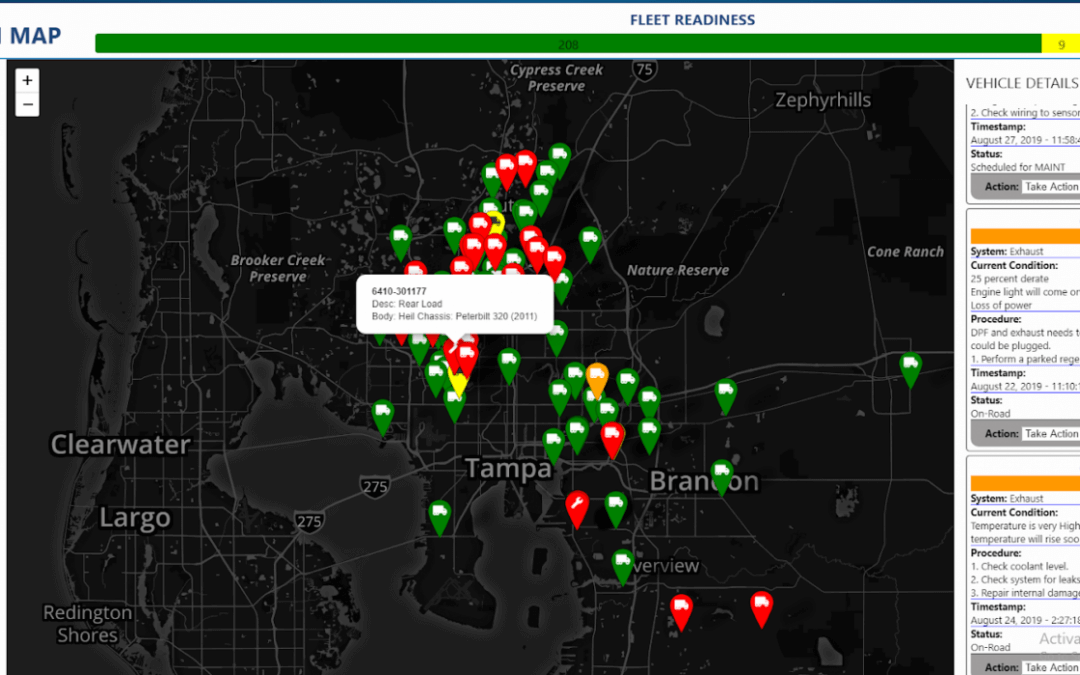

When looking to reduce the costs of a working vehicle fleet, it’s all about preventative care. Fleet maintenance management which is focused on preventing breakdowns and other problems will ultimately pay off by significantly reducing ongoing costs, preventing work stoppages, and of course, helping protect your drivers and operators.

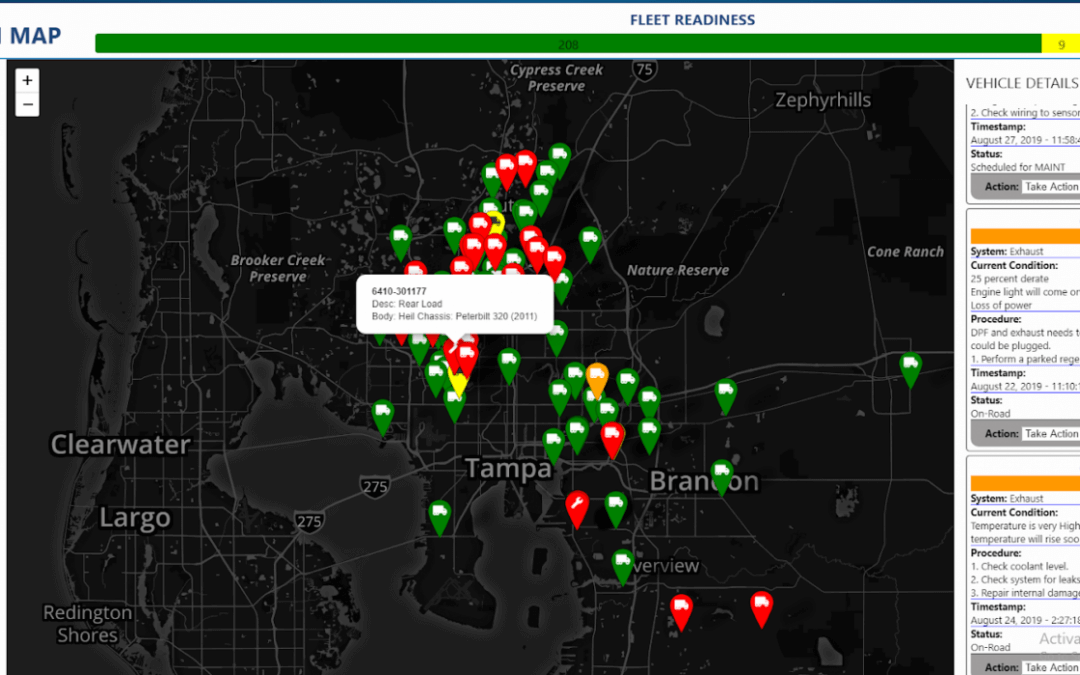

Today, it’s easier than ever with data-based systems. A combination of real-time sensors on the vehicle and computer software collating the data allows you to see vehicle performance stats at a truly granular level. This makes preventative maintenance far easier to accomplish, while further improving your cost savings!

Four Ways Data-Based Fleet Maintenance Management Prevents Needless Costs

1 – Smart alerts

If a particular vehicle is due for an oil change, how would you know? Are the brakes on a vehicle within their operational lifespan, or have they passed the expected EOL? These sorts of issues could require a lot of time and attention to keep on top of – except now because software can do it for you. Modern fleet management systems can store purchase dates, maintenance records, end-of-warranty information, and more – sending you alerts whenever a needed bit of maintenance is coming up.

2 – Tracking tire pressure and status

Modern vehicles are able to closely monitor the status and performance of their tires, and that translates into highly useful data for you! You’ll be able to see tire pressure and tire age for every vehicle, which can also be cross-referenced with other statistics such as acceleration and braking times. Combined, this means you’ll know exactly which tires are beginning to underperform, allowing you to repair or replace them before they become unreliable.

3 – Prevent regulatory woes

Numerous aspects of your vehicles must be officially inspected and\or certified. Keeping up with those can be another major headache. However, this is another area where fleet maintenance management software shines. It can keep track of the legal side of fleet management, and ensure you know whenever a vehicle is in danger of non-compliance.

4 – Protect your drivers on the road

A smart vehicle monitoring system receives updates in real-time. That means you could potentially become aware of a problem on the road, such as low fluids before the driver even notices. So, even more problems can be avoided while keeping your drivers safe from accidents.

Vehicle Licensing Consultants (VLC)

VLC has years of experience making it easier for fleet managers to oversee and maintain their fleet! Click here to learn more about our services.

Fleet Management

Tips For Fleet Maintenance Management Best Practices

For 28 years, Vehicle Licensing Consultants (VLC) have been working hard to help shipping operations of all sizes improve their efficiency and productivity. We are fleet maintenance management specialists, with a range of consulting services and software packages that make your life easier while improving your bottom line.

So, what are the most important elements of fleet maintenance management in the 2020s? These are the areas we often suggest our customers focus on.

Four Critical Areas of Fleet Maintenance Management

1 – Establish clear, measurable, achievable goals

This is the foundation of all good fleet maintenance and good business growth in general. You should set clear goals and metrics for operations, and then measure progress towards those metrics over time. They should always be expressed in well-defined terms, preferably with hard numbers attached, so there’s no ambiguity about expectations.

This can include elements such as:

- Reducing accidents or traffic violations

- Optimizing fuel use

- Reducing delivery times

- Improving vehicle value / reducing depreciation

- Customer satisfaction levels

A company that doesn’t have clear-cut goals will struggle to improve in a reasonable fashion.

2 – Constant monitoring and data-tracking of vehicles

We’re not just talking about on-the-road monitoring here. Every possible aspect of your vehicles should be monitored and recorded for data analysis. Repairs, part lifespans, mileage, standards compliance, warranty terms, fuel efficiency… Every aspect of your fleet can potentially be analyzed looking for new opportunities for cost-cutting or improved profitability – but only if you’re tracking the data.

3 – Driver management

It’s every bit as important to monitor your drivers with the same level of detail as your vehicles. This can include overall route drive times, adherence to safety regulations, accidents, fuel-conservation strategies, and more. These can be tied back to your operational goals so that you can encourage driving behavior that best aligns with those goals. For example, are you more concerned with speed or fuel efficiency? Either could be the right answer, but you should be able to give your drivers clear guidance on which you’re optimizing for.

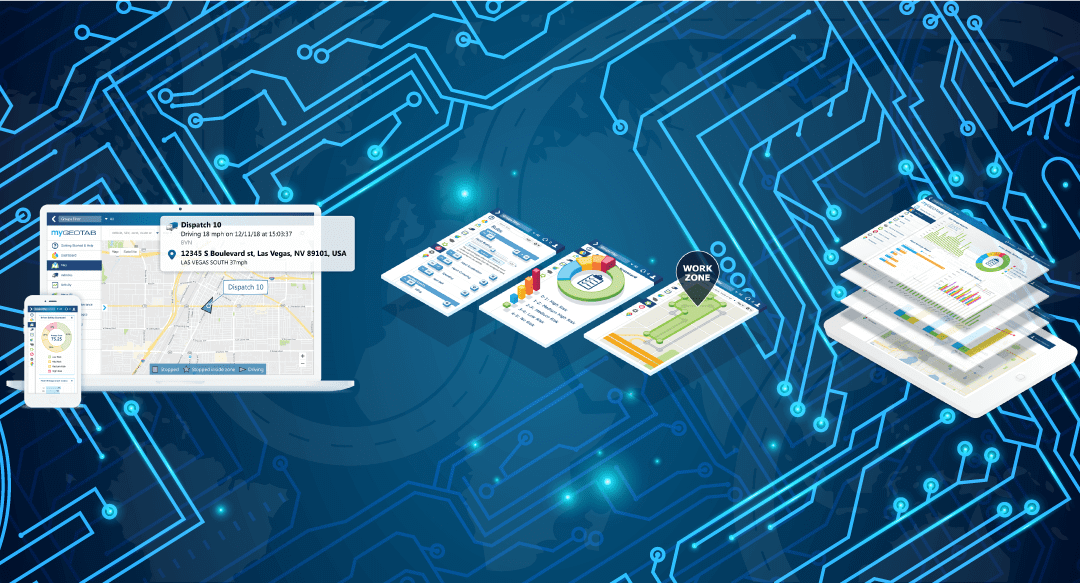

4 – Have robust fleet management software

Fleet management software is the backbone of every good trucking operation. It should be able to handle basic routing, hold data on your vehicles and drivers, and hopefully integrate your customer relationship management database as well. Having all information at your fingertips makes day-to-day operations so much easier.

VLC consulting and software can help your fleet achieve maximum efficiency! Click here to learn more.